Difference between revisions of "Assembly Guide"

| Line 74: | Line 74: | ||

=== Soldering Workflow === | === Soldering Workflow === | ||

| + | [[File:Closeup of one soldered pad and a resistor.jpg|thumb|right|Closeup of a pad with solder and a resistor]] | ||

Take your BOM and choose one of the resistor values to begin with and identify the pad label, where the resistor is supposed to be placed. | Take your BOM and choose one of the resistor values to begin with and identify the pad label, where the resistor is supposed to be placed. | ||

Now take your soldering iron and heat one side of the pad. After a couple of seconds of heating, add some solder to the pad. | Now take your soldering iron and heat one side of the pad. After a couple of seconds of heating, add some solder to the pad. | ||

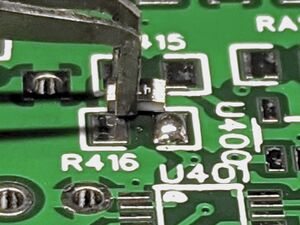

Take out one of the resistors out of it's packaging and grab onto it with the tweezers as indicated in the picture on the right. | Take out one of the resistors out of it's packaging and grab onto it with the tweezers as indicated in the picture on the right. | ||

| − | |||

Heat the solder blob and slide the component into the molten solder from the side. | Heat the solder blob and slide the component into the molten solder from the side. | ||

This ensures covering of the components contacts. | This ensures covering of the components contacts. | ||

| Line 84: | Line 84: | ||

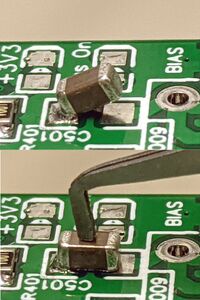

Doing this will help to mount the component flush to the board. | Doing this will help to mount the component flush to the board. | ||

Although not always necessary, doing this will help to avoid solder bridges, especially between the legs of ICs. | Although not always necessary, doing this will help to avoid solder bridges, especially between the legs of ICs. | ||

| − | [[File:Flush component.jpg| | + | [[File:Flush component.jpg|x300px|thumb|right|Component lifted on one side (top); pressed down and after remelting the solder (bottom)]] |

| + | |||

=== Integrated Circuits (ICs) === | === Integrated Circuits (ICs) === | ||

| − | {{#evt:service=youtube|id=E3kZMtjD76c|alignment=right|container=frame|description=Timelapse of IC soldering|dimensions= | + | {{#evt:service=youtube|id=E3kZMtjD76c|alignment=right|container=frame|description=Timelapse of IC soldering|dimensions=480}} |

| − | }} | ||

Revision as of 16:54, 7 December 2020

[WORK IN PROGRESS] This is a guide on how to populate our MuonPi-PCB, using the construction kit. You can get a kit or a fully assembled PCB by contacting us here.

All components in this kit (except for the pin headers) are surface-mount devices (SMD). Most of these parts are only a few millimeters in size and are prone jump very far, should you slip with the tweezers. Soldering these requires steady hands and a bit of technique, but this guide aims to help you with that.

Contents

The Kit

The Kit contains all the parts you need to set up your very own particle detector using your RaspberryPi.

Contents of the Kit are:

- The plastic scintillator (generously provided by Eljen Technology)

- The bare printed circuit board (Muonpi board)

- GNSS antenna

- Components to mount on the PCB (Resistors, Capacitors, Inductors, ICs, etc.)

- Bill of materials (BOM)

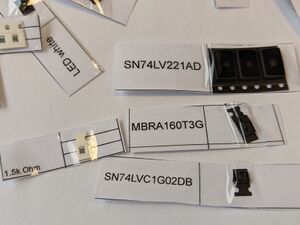

The individual components of the kit are glued to a nametag using tape, as can be seen in the picture.

Unfortunately getting the parts out of their packaging will take half of the time spent on assembly. Be careful when you unpack these parts, they can get lost very easily

Tools

The bare essential tools are:

- soldering iron

- solder

- (metal) tweezers

- solder fume extractor

additional:

- flux

- solder wick

- vise or helping hands

- scalpel/scissors

- magnifying glass

Additionally, we recommend to choose a brightl workplace, as dim lights and small components can lead to eye strain and head aches.

Generally,the smaller the tip of your soldering iron is, the better, for small component soldering at least.

Of course if you have other solder tips, like ones with a solder depot, you can use those too.

In any case whatever tools you need to get the job done, are the correct tools to use.

Documentation

The schematic, layout and BOM of the current hardware version can be found on the easyEDA project page. While soldering, finding the right pad, where a specific components has to go, can be quite difficult. The labels on the PCB are small and space for them is very limited which makes some of them hard to read and find. To help you find the correct solder pads, we recommend to have a computer nearby where you can open the schematics and use the search function. Alternatively you can print out the layout that is attached on the easyEDA project page.

Mounting Options

The BOM specifies multiple mounting options, such as: "Full", "Single Channel", "External Bias Supply", "Fixed Input Polarity". "External Bias Supply" and "Fixed Input Polarity" were used by us in the development and will not be discussed here further. The default configuration of the kit contains only one scintillator, therefore only one channel of the detector electronics will be used at a time. In that case, the "Single Channel" mounting option would be sufficient. However the number of components in the kit follows the "Full" configuration, and mounting all components is still recommended. Just mounting all the parts that are included in the kit will lead to a working PCB with both channels working. Please contact us, if you are interested in a two scintillator setup.

Assembly

First things first, you should setup your workspace with all parts layed out, along with the BOM and all the tools you might need. Personally, I like to sort the parts into categories: Resistors, Capacitors, Inductors, ICs and others. This helps to save time and gives a quick overview of your soldering progress. In principle the choice which components to mount first comes down to personal preference. A helpful guideline is to mount parts depending on their height. Lower, smaller parts should be mounted first, as to not interfere too much in the later stages of assembly. This is why the GPIO headers should be among the last components to be mounted.

Once you are set up, you can turn on your soldering iron and fume extractor and start soldering.

Tips on SMD soldering

SMD components are small and difficult to solder.

The easiest components to solder are the resistors and capacitors.

Start with these to get comfortable with SMD soldering first, then proceed to the more difficult ICs.

A quick guide to SMD soldering can be found at sparkfun.com.

Soldering Workflow

Take your BOM and choose one of the resistor values to begin with and identify the pad label, where the resistor is supposed to be placed. Now take your soldering iron and heat one side of the pad. After a couple of seconds of heating, add some solder to the pad. Take out one of the resistors out of it's packaging and grab onto it with the tweezers as indicated in the picture on the right. Heat the solder blob and slide the component into the molten solder from the side. This ensures covering of the components contacts. Placing the component into the blob from above can lead to solder bridges underneath the component, which will render the component useless. Once one side of the component is fixed, it's good practice to lightly press down on the component and remelt the solder. Doing this will help to mount the component flush to the board. Although not always necessary, doing this will help to avoid solder bridges, especially between the legs of ICs.