Difference between revisions of "The Detector"

| (16 intermediate revisions by 4 users not shown) | |||

| Line 3: | Line 3: | ||

__TOC__ | __TOC__ | ||

| − | = Material List = | + | = How the detector works = |

| + | |||

| + | Simple working principle based on the scintillator and SiPM page, putting it in context with our project. | ||

| + | |||

| + | = How to build a muon detector = | ||

| + | |||

| + | == Material List == | ||

Independent of the size and shape of the scintillator the following materials and tools are used for building a scintillator detector: | Independent of the size and shape of the scintillator the following materials and tools are used for building a scintillator detector: | ||

[[File:Detector Assembly 001.jpg|thumb|Fully-wrapped detectors with label]] | [[File:Detector Assembly 001.jpg|thumb|Fully-wrapped detectors with label]] | ||

| Line 18: | Line 24: | ||

* Scalpel | * Scalpel | ||

* Scissors | * Scissors | ||

| + | * Tweezer | ||

| − | = Assembly Steps = | + | == Assembly Steps == |

| − | # '''Cutting the Kapton stencil:''' The stencil is used as a template and carrier for cutting the thin Teflon and aluminum foil. It is usually cut in the same base shape as the scintillator but slightly larger to accommodate the edges of the scintillator. | + | # '''Cutting the scintillator:''' In the case for the MuonPi detectors the scintillators are provided as plates of 10x250x250 mm^3. Depending on the [[#Detector geometry|desired geometry]], the scintillators are cut with a circular saw to fit the design. Afterwards, all edges are polished. |

| − | # '''Cutting and wrapping the Teflon foil:''' The thin layer of Teflon foil is unrolled and laid out on top of the stencil, removing all wrinkles carefully. Guided by the outlines of the stencil the Teflon foil is cut using a sharp scalpel. Depending on the desired thickness of the Teflon on the scintillator, this step is repeated several times. Finally, the scintillator is placed with its top face centered on top of the Teflon cut-out and the surplus of Teflon is carefully folded upwards to cover the edges of the scintillator. Now the scintillator can be flipped such that the top faces downwards and the stencil is carefully removed. To cover the other face this step is repeated. | + | # '''Cutting the Kapton stencil:''' The stencil is used as a template and carrier for cutting the thin Teflon and aluminum foil. It is usually cut in the same base shape as the scintillator but slightly larger to accommodate the edges of the scintillator. The stencil is reusable and only has to be crafted once. |

| + | # '''Cutting and wrapping the Teflon foil:''' The thin layer of Teflon foil is unrolled and laid out on top of the stencil, removing all wrinkles carefully. Guided by the outlines of the stencil, the Teflon foil is cut using a sharp scalpel. Depending on the desired thickness of the Teflon on the scintillator, this step is repeated several times. Finally, the scintillator is placed with its top face centered on top of the Teflon cut-out and the surplus of Teflon is carefully folded upwards to cover the edges of the scintillator. Now the scintillator can be flipped such that the top faces downwards and the stencil is carefully removed. To cover the other face, this step is repeated. | ||

# '''Cutting and wrapping the aluminum foil:''' The aluminum foil, while using the stencil, is prepared and attached to the scintillator in a similar fashion. The foil is fixed with reflective tape. | # '''Cutting and wrapping the aluminum foil:''' The aluminum foil, while using the stencil, is prepared and attached to the scintillator in a similar fashion. The foil is fixed with reflective tape. | ||

| − | # '''Cutting and taping the pond liner:''' A layer of thick pond liner is used to cover both faces of the scintillator. For this, the base shape of the scintillator is used to cut the liner. Using double-sided tape the liner is glued on both faces. | + | # '''Cutting and taping the pond liner:''' A layer of thick pond liner is used to cover both faces of the scintillator. For this, the base shape of the scintillator is used to cut the liner. Using double-sided tape, the liner is glued on both faces. |

# '''Taping the edges:''' Black tape is used to cover all left-over uncovered spots of the scintillator apart from the light-collection faces. Now the scintillator is ready to be coupled with the photo-detector. | # '''Taping the edges:''' Black tape is used to cover all left-over uncovered spots of the scintillator apart from the light-collection faces. Now the scintillator is ready to be coupled with the photo-detector. | ||

| − | # '''Attaching the SiPM:''' The SiPM sitting on its PCB chip and equipped with a reflective mask is covered with a small amount of optical grease and is pressed | + | # '''Attaching the SiPM:''' The SiPM sitting on its PCB chip and equipped with a reflective mask is covered with a small amount of optical grease and is pressed against the light collection surface. While maintaining the pressure, the chip is fixed to the scintillator with black tape. Since the preamplifier and the SiPM are designed modular, the preamplifier chip can be plugged on top of the SiPM chip. |

<gallery mode="packed-hover"> | <gallery mode="packed-hover"> | ||

Detector_Assembly_002.jpg|Kapton stencil and tools | Detector_Assembly_002.jpg|Kapton stencil and tools | ||

| Line 34: | Line 42: | ||

Detector_Assembly_006.jpg|Layer of pond liner added | Detector_Assembly_006.jpg|Layer of pond liner added | ||

</gallery> | </gallery> | ||

| + | |||

| + | We have a '''time lapse video of a full detector assembly run''' on YouTube [https://www.youtube.com/watch?v=7_O-eDJvdJU here]. | ||

| + | |||

| + | = Detector Specifications = | ||

| + | Our detectors come in many different geometries and configurations. | ||

| + | == Detector Geometry == | ||

| + | Several different detector geometries can be build from the raw scintillator plates of type EJ-248M provided by our supplier [https://eljentechnology.com/products/plastic-scintillators Eljen]. The uncut scintillator plates have a dimension of 10x250x250 mm^3. Additionally, we recycle former hexagonal "veto" plastic scintillators from the TAPS detector of the [https://wwwa2.kph.uni-mainz.de/a2detector-system/ A2 detector system] | ||

| + | === The Original === | ||

| + | The original detector geometry is chosen to maximize the light collection efficiency while having a large area for a high muon count rate. This geometry was determined both experimentally <ref>L. Nies, ''Development of a SiPM-based readout-module for the characterization of various scintillation materials'', (University of Giessen, Bachelor Thesis, August 2017), [https://www.uni-giessen.de/fbz/fb07/fachgebiete/physik/institute/iipi/arbeitsgruppen/ag-brinkmann/forschung/theses/Nies_Lukas_BSc_Thesis_SiPM.pdf link]</ref> and theoretically <ref>S. Peter, ''Simulation of Cosmic Air Showers and Simulation Studies for the Geometry Optimization of a Scintillation Detector'', (University of Giessen, Bachelor Thesis, September 2019), [https://www.uni-giessen.de/fbz/fb07/fachgebiete/physik/institute/iipi/arbeitsgruppen/ag-brinkmann/forschung/theses/Bachelor_Sven_Peter.pdf link]</ref> to yield the best performance for a given detector area. | ||

| + | === The Original - Half Size === | ||

| + | The U-BLOX chip can only assign accurate timestamps to a limited amount of events per second. A high muon flux can lead to a large dead time (time interval in which the detector is "blind" to events). With the Original type detector, we currently (HAT version 3.1) encounter a deadtime of 20% to 30%, depending on the threshold level. In practice, this means that we lose about one-third of all events. From an economic point of view, it makes sense to reduce the detector size to reduce the muon flux to reduce the dead time. Cutting the Original in half makes the detector more efficient and results in a dead time factor of about 10%. | ||

| + | === The Hexagonal === | ||

| + | Reusing the "veto" plastic scintillators from the TAPS detector, we have an excellent small and versatile detector for measuring cosmic muons. Significantly smaller than the standard type, the detector dead time (factor of roughly 5%) imposes no problem. | ||

| + | |||

| + | <gallery mode="packed-hover"> | ||

| + | scintillator_original_geometry.png|Original Geometry | ||

| + | scintillator_original_half_geometry.png|Original Half Geometry | ||

| + | scintillator_hex_geometry.png|Hex Geometry | ||

| + | </gallery> | ||

| + | |||

| + | == Detector label == | ||

| + | The detectors are labeled for proper documentation after the assembly. On the label, the following information about the detector is persisted: | ||

| + | * The detector's serial number (SN) which allows us to trace the history of a detector. | ||

| + | * The scintillator base material | ||

| + | * The type of the SiPM photosensor | ||

| + | * How the SiPM sensor is configured. For multiple-SiPM readout, several possible configurations exist, such as parallel, series or hybrid. | ||

| + | * The operation voltage (reverse bias) at which the detector was tested. | ||

| + | * Date of assembly and signature of the assembling person | ||

| + | |||

| + | [[File:Detector-label_new.png|thumb|Label for the detectors.]] | ||

| + | |||

| + | = References = | ||

| + | <references /> | ||

Latest revision as of 11:18, 4 November 2021

The current detector design is based on a plastic scintillator, wrapped in different types of foil, and a Silicon Photomultiplier for the collection of scintillation light. In this article, the assembly of a detector module will be explained.

Contents

How the detector works

Simple working principle based on the scintillator and SiPM page, putting it in context with our project.

How to build a muon detector

Material List

Independent of the size and shape of the scintillator the following materials and tools are used for building a scintillator detector:

- Kapton stencil

- Teflon foil

- Aluminum foil

- Reflective foil

- Black tape

- Pond liner (thick black foil)

- Optical grease

- Scintillator

- Silicon Photomultiplier (SiPM) on PCB chip

- Preamplifier

- Scalpel

- Scissors

- Tweezer

Assembly Steps

- Cutting the scintillator: In the case for the MuonPi detectors the scintillators are provided as plates of 10x250x250 mm^3. Depending on the desired geometry, the scintillators are cut with a circular saw to fit the design. Afterwards, all edges are polished.

- Cutting the Kapton stencil: The stencil is used as a template and carrier for cutting the thin Teflon and aluminum foil. It is usually cut in the same base shape as the scintillator but slightly larger to accommodate the edges of the scintillator. The stencil is reusable and only has to be crafted once.

- Cutting and wrapping the Teflon foil: The thin layer of Teflon foil is unrolled and laid out on top of the stencil, removing all wrinkles carefully. Guided by the outlines of the stencil, the Teflon foil is cut using a sharp scalpel. Depending on the desired thickness of the Teflon on the scintillator, this step is repeated several times. Finally, the scintillator is placed with its top face centered on top of the Teflon cut-out and the surplus of Teflon is carefully folded upwards to cover the edges of the scintillator. Now the scintillator can be flipped such that the top faces downwards and the stencil is carefully removed. To cover the other face, this step is repeated.

- Cutting and wrapping the aluminum foil: The aluminum foil, while using the stencil, is prepared and attached to the scintillator in a similar fashion. The foil is fixed with reflective tape.

- Cutting and taping the pond liner: A layer of thick pond liner is used to cover both faces of the scintillator. For this, the base shape of the scintillator is used to cut the liner. Using double-sided tape, the liner is glued on both faces.

- Taping the edges: Black tape is used to cover all left-over uncovered spots of the scintillator apart from the light-collection faces. Now the scintillator is ready to be coupled with the photo-detector.

- Attaching the SiPM: The SiPM sitting on its PCB chip and equipped with a reflective mask is covered with a small amount of optical grease and is pressed against the light collection surface. While maintaining the pressure, the chip is fixed to the scintillator with black tape. Since the preamplifier and the SiPM are designed modular, the preamplifier chip can be plugged on top of the SiPM chip.

We have a time lapse video of a full detector assembly run on YouTube here.

Detector Specifications

Our detectors come in many different geometries and configurations.

Detector Geometry

Several different detector geometries can be build from the raw scintillator plates of type EJ-248M provided by our supplier Eljen. The uncut scintillator plates have a dimension of 10x250x250 mm^3. Additionally, we recycle former hexagonal "veto" plastic scintillators from the TAPS detector of the A2 detector system

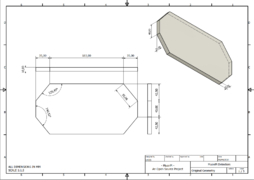

The Original

The original detector geometry is chosen to maximize the light collection efficiency while having a large area for a high muon count rate. This geometry was determined both experimentally [1] and theoretically [2] to yield the best performance for a given detector area.

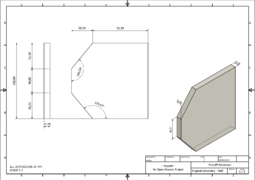

The Original - Half Size

The U-BLOX chip can only assign accurate timestamps to a limited amount of events per second. A high muon flux can lead to a large dead time (time interval in which the detector is "blind" to events). With the Original type detector, we currently (HAT version 3.1) encounter a deadtime of 20% to 30%, depending on the threshold level. In practice, this means that we lose about one-third of all events. From an economic point of view, it makes sense to reduce the detector size to reduce the muon flux to reduce the dead time. Cutting the Original in half makes the detector more efficient and results in a dead time factor of about 10%.

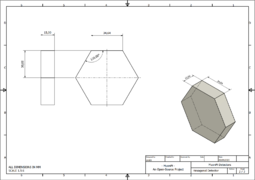

The Hexagonal

Reusing the "veto" plastic scintillators from the TAPS detector, we have an excellent small and versatile detector for measuring cosmic muons. Significantly smaller than the standard type, the detector dead time (factor of roughly 5%) imposes no problem.

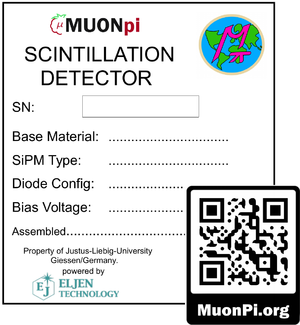

Detector label

The detectors are labeled for proper documentation after the assembly. On the label, the following information about the detector is persisted:

- The detector's serial number (SN) which allows us to trace the history of a detector.

- The scintillator base material

- The type of the SiPM photosensor

- How the SiPM sensor is configured. For multiple-SiPM readout, several possible configurations exist, such as parallel, series or hybrid.

- The operation voltage (reverse bias) at which the detector was tested.

- Date of assembly and signature of the assembling person

References

- ↑ L. Nies, Development of a SiPM-based readout-module for the characterization of various scintillation materials, (University of Giessen, Bachelor Thesis, August 2017), link

- ↑ S. Peter, Simulation of Cosmic Air Showers and Simulation Studies for the Geometry Optimization of a Scintillation Detector, (University of Giessen, Bachelor Thesis, September 2019), link